Alloy wire

Self-Bonding Round Wire

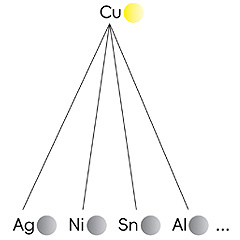

Alloy Self-Bonding Enamelled Wire

Alloy self-bonding enameled wire uses alloy instead of copper as a conductor. The insulating coat is generally made of polyurethane material, and the bonding coat is polyamide material to achieve an adhesive effect. Compared with ordinary self-bonding enameled wire, the advantages of this product are mainly reflected In terms of the physical properties of the conductor material (mechanical properties, electrical conductivity, bending resistance), it is used for high-performance coils(such as various types of speakers, voice coils, and consumer electronics coils).

Product Features

● Excellent size control.

● Excellent bending resistance and Breaking force resistance.

● Good high temperature resistance and antibacterial properties.

● Excellent reliability.

● Thermal class: 155 , 180 , 200 and above.

● Specification range: 0.002-0.300mm .

● Tensile strength: ≥320Mpa

● Bending resistance: > 1500 times

Application Area

This product is widely used in: speakers, high-frequency leads, voice coils, consumer electronics, and textiles due to its excellent mechanical and electrical conductivity.

Main Features

● The bending resistance of alloy wires is greatly improved, and the bending life is 15 to 36 times that of copper materials of the same specification.

● Compared with copper materials of the same specifications, the mechanical properties are greatly improved, but the conductivity can still be close to that of copper wires.

● Customization for customers, it can be made into multi-strand litz wire or mylar wire.

● Excellent dyeable performance, can easily meet the color requirement of the customer.

Advantages Of Huaye

For this type of product, Huaye purchases the alloy conductor from top-quality professional material suppliers in the industry and uses single-head equipment to produce them. All machines are equipped with real-time online dimension monitoring systems for conductor and coating films to ensure The high quality of the product.

Data Comparison

Note: All typical values of Huaye New Materials are based on the results of Ø 0.080mm thin paint film experiments, and there may be deviations.

Dongguan Base

Tel: +86-769-8223-6800

Contact: Mr. Deng +86-158-1685-6940

Contact person: ms fan +86-135-0980-6566

Address: No.4, No.6 Road, Jinshagang, Dalang Town, Dongguan City, Guangdong Province

Xianning Base

Tel: +86-715-8101-600

Contact: Mr. Peng +86-150-6858-9744

Contact:Ms. Xu :+86-136-3163-8124

Address: Building 2, No. 769 He Sheng Road, High-tech Yangtze River Industrial Park, Xianning City, Hubei Province (Intelligent Manufacturing Industrial Park)

Copyright © Hubei Zhongke Huaye New Material Technology Co., Ltd.

This website supports IPV4 / IPV6 bidirectional access