Silk-wrapped wire

Silk-wrapped wire

Definition

Litz wire is composed of multiple strands of insulated wire and is widely used in applications requiring good flexibility and high-frequency performance. High-frequency litz wire is formed by twisting multiple insulated wires that are mutually insulated, typically used in applications with operating frequencies between 10kHz and 5MHz. In the application of magnetic energy storage coils, high frequency can cause eddy current losses. Eddy current losses increase with the frequency of the current, and these losses are caused by the skin effect and proximity effect. High-frequency litz wire can effectively reduce the losses caused by the 'skin effect' and 'proximity effect' in high-frequency applications.

Single insulated wire

The basic unit of litz wire is a single enameled wire, which can be optimized in various combinations of conductor materials and insulating materials to meet different application needs.

Structure

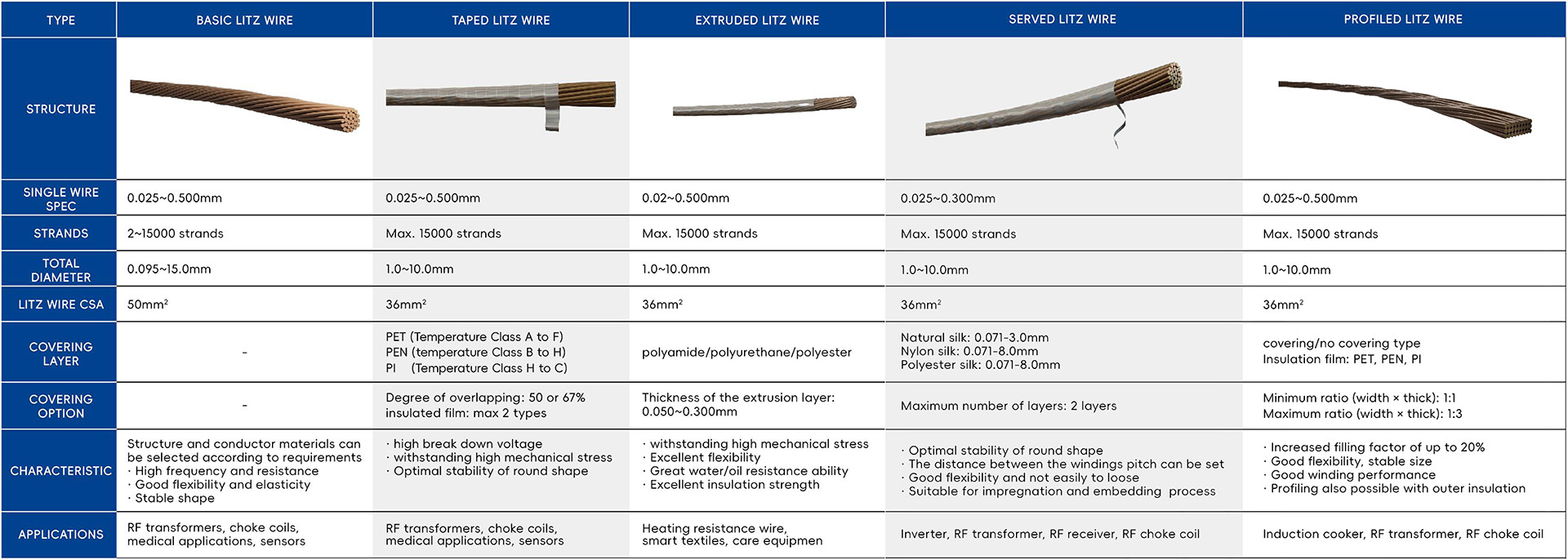

The number of strands in a single enameled wire can be twisted once or multiple times, allowing for various design choices in the structure of litz wire.

Additionally, various forms of outer insulating materials can be combined based on application needs, such as coating films (PET, PEN, PPS, PI, etc.), coated fibers (natural silk, nylon, polyester, etc.), and extruded materials.

Types of litz wire

Product Features

Application Area

Based on the number of strands of a single enameled wire, it can be twisted once or multiple times, allowing for various design options in the structure of Leeds wire. Additionally, various forms of outer coating materials can be combined on the outer layer according to application needs, such as coating films (PET, PEN, PPS, PI, etc.), coating fibers (natural silk, nylon, polyester, etc.), and extruded material coatings.

Production Scope

Table Download

Advantages Of Huaye

Dongguan Base

Tel: +86-769-8223-6800

Contact: Mr. Deng +86-158-1685-6940

Contact person: ms fan +86-135-0980-6566

Address: No.4, No.6 Road, Jinshagang, Dalang Town, Dongguan City, Guangdong Province

Xianning Base

Tel: +86-715-8101-600

Contact: Mr. Peng +86-150-6858-9744

Contact:Ms. Xu :+86-136-3163-8124

Address: Building 2, No. 769 He Sheng Road, High-tech Yangtze River Industrial Park, Xianning City, Hubei Province (Intelligent Manufacturing Industrial Park)

Copyright © Hubei Zhongke Huaye New Material Technology Co., Ltd.

This website supports IPV4 / IPV6 bidirectional access